Reinstall the transmission, reconnect parts, and take a look at the clutch operation. Erratic shifting, harsh gear adjustments, or transmission slipping are frequent signs. In some instances, the transmission may go right into a “limp mode,” limiting the gear range to prevent further damage. Illuminated warning lights on the dashboard also continue can point out issues. Electronic management modules or transmission control modules oversee this, utilizing knowledge from sensors to manage the transmission’s inner parts. In some instances, the clutch may slip, inflicting the engine to rev and not using a corresponding improve in the vehicle’s velocity.

During our steel 3D printing member webinar on May 1, greater than 25 questions were fielded by Dr. Rogers by the more than 60 attendees. He provided info on the most important size gears that can be made using laser-powder fusion. On most machines, it is 9.5 inches sq.; however, the largest machines out there have 500mm x 800mm construct platforms, so there may be the likelihood for something in the realm of 15 to 17 inches in diameter. He described the accuracy for laser sintered parts is plus-or-minus about 0.1mm, however that it does vary by software and system. While AM methods were invented greater than 30 years in the past, they were primarily thought for use to customize the environment. It has solely been in current years that these processes are being looked at and developed as a mass production expertise.

Electrical Car Awards 2024: Greatest Hybrid Family Car

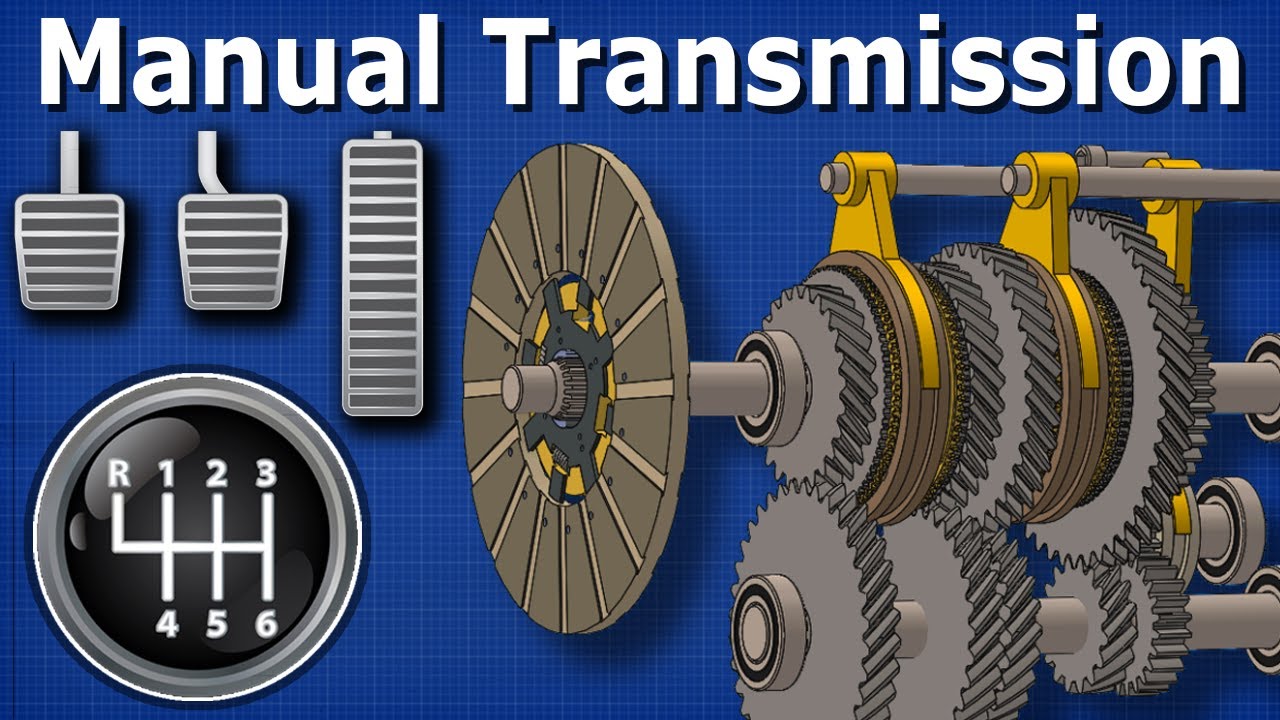

These materials not solely make gears stronger but in addition extra eco-friendly, addressing the stringent emission regulations. Another much less common kind of automatic transmission is called a twin clutch transmission, or DCT. In a DCT, there are literally two separate clutches that management even and odd gears.

Lighter Gears, Higher Gas Economy

The current inspection course of used by an automotive gear producer in Guelph, Ontario, requires human operators to visually inspect all gear produced. In this work, we propose a machine imaginative and prescient system for automating the inspection course of for gears with broken teeth defects. The applied inspection system makes use of a faster R-CNN community to identify the defects, and combines domain knowledge to reduce the guide inspection of non-defective gears by 66%.